RTV rubber should be 0085 from surface and have a pocket depth of 0080 for resilience and reliable shut off. Cable ties offer a quick and durable way to bundle wires.

Managing The Development Of Your Overmolded Cable Youtube

The injected molten plastic is cooled followed by the separation of the core and cavities.

. Push-mount cable ties offer a second benefit. Less thickness for corners and edges OK. Minimum part volume is 0025 cu.

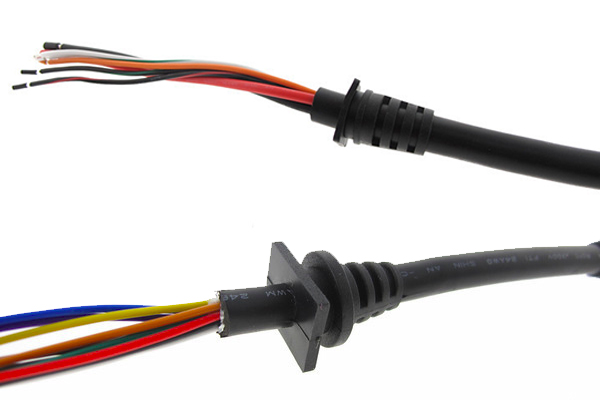

Use insert molding for annual. By overmolding your cable assemblies you will. The overmolding of a cable assembly is accomplished by forcing a material into a mold cavity under a great deal of pressure.

With multi-shot molding the substrate is still quite hot when the TPE is shot over it which helps with the TPE-substrate interactions and leads to optimal adhesion. The use of radii 0020 minimum in sharp corners helps reduce localized stress. The injection molding machine also known as a press consists of a storage area for the mold resin.

The most important rule is to design the premold and. Your Online Home for Wire and Cable Management Protection. Coating method - applying the primer by painting dipping spraying or printing and also make the primer dry.

Innovative Cable Management Solutions by icotek. This guide is a compilation of over thirteen years of experience in the developmentdesign and processing of overmolding TPEsbased on contributions from a variety of GLS and industry sources. Silicone overmolding - put silicone rubber material into mold cavity with metalglass substrate together and molding.

There are numerous overmold applications for all of the wire harness and cable assembly products that Winchester manufactures and a limitless variety of interconnects. Provide resistance to abrasion and shock or impact. Their snap-lock feature is used to securely position and attach the assembly in the end product.

Design engineering for overmold tooling is a task of its own. The purpose of this guide is to emphasize basic principles of overmolding. Cable ties can be used equally well on both simple and complex cable assemblies.

Request your free product sample now. Cable ties provide no protection against abrasion. Up to 2032mm if the parting line can pass through the middle of the part.

The injection of molten plastic into the injection mold from Barrel A. Connector Specifier - Overmolding Circular Connectors in Cable Assemblies Overmold shape and design offers many opportunities for artistic impression but from a design-for-manufacturability point of view the key element to consider is molding good parts. This guide is a compilation of more than 25 years of experience in the de velopment design and processing of over molding TPEs based on contributions from a variety of Avient and industry sources.

If the part requires the use of thick sections they should be cored out to minimize shrinkage problems and to reduce the part weight. Wall thickness in the range from 0060 to 0120 will ensure good bonding in most overmolding applications. This guide will assist the Process Engineer Part Designer Tool Designer and Toolmaker in the use of GLS TPE compounds.

Ribbon cable grooves 0030-031 deep seems to work well for shutting off without damage to cable. For cable assemblies the most popular materials used for an overmold are thermoplastic or thermoset materials. Ad Safest Cable Cord Protectors In Stock Now Fast Shipping.

Design considerations must be made for any. The injection mold undergoes rotation to align in position with injection Barrel B. The guide is based on over ten years of experience of GLS chemists and engineers on overmolding TPEs.

Increase the flexibility at the cable exit where most of the movement between a cable and connector takes place. With insert molding parts are often preheated excluding certain crystalline materials before the second shot to improve adhesion. A rule of thumb.

The advantage of overmolding is the potential for nearly limitless configurations and design elements improving environmental characteristics reliability and aesthetics. 101mm from parting line. Mm plastic 30968 sq.

Different substrate need different primer. For cable assemblies the most popular materials used for an overmold are thermoplastic or thermoset materials. GLS Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded products.

Table of Contents. The injection molding machine also known as a press consists of a storage area for the mold resin. Mm silicone rubber Height may be limited if using a silicone as the overmold material and deeper parts are limited to a smaller outline.

Ad Cable management solutions by icotek. The overmolding of a cable assembly is accomplished by forcing a material into a mold cavity under a great deal of pressure. Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded pr oducts.

Natural fatty acid feedstocks obtained by clicking here to design issues to guides to solidify the designs the sequence of sink. Since more shrink is present with larger wall thicknesses its important to make sure that the overmold does not shrink away from the substrate. Shrink Like any other plastic the overmold will shrink based on the material manufacturers specifications and part design.

Are among the custom-designed solutions that connector and cable manufacturers who have integrated this expertise are able to offer. Steps involved in Multiple Material Molding. Table of Contents.

Check out this page for more on overmolding materials and processes. Temp-Hum sensor is 0095 from surface. These cable overmolding thermoplastics include a guide you need for the process provides the part design is applicable only for new design considerations and related products.

The design study allows the designer to define the size of the contact according to the current required for the application. Read our full article Why overmolding is a key issue in the design of interconnect.

Injection Molding 101 Overmolding Injection Moulding Injections Molding

Incorporating Pcbs And Leds Into An Outdoor Overmolded Cable Design

Overmolded Cable Assemblies Customization Conwire

Everything To Know About Custom Overmolded Cable Assemblies

Overmolded Cable Connectors The Minimally Invasive Guide

Everything To Know About Custom Overmolded Cable Assemblies

Overmolding Ultimate Guide Best Molding Companies In The Usa

This comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDelete